For over 100 years, Hardinge lathes have been and will continue to be a standard for quality, longevity and capability. Whether it is high volume production or holding tight tolerances, Hardinge can provide you with the right CNC lathe solution every time. See all Turning products.

Hardinge Manual's PDF Download. HLV-H & TFB-H New Style Operator Manual; HLV-H Old Style Operator Manual; HLV-H & TFB-H Maintenance Manual; HLV-H & TFB-H Parts List; HLV-H New Style Electrical Schematic; HC Maintenance Manual; HC Parts List; DV-59 & DSM-59 Operator & Maintenance Manual; DV-59 & DSM-59 Parts List; Cataract Lathe 1917. Hardinge HLV-H Lathe Operator's Detailed Instruction Manual with screwcutting charts. Full 65-page version - also covers the Feeler FTL-618 and other Taiwanese machines such as the AML, Barer, Cyclematic, South Bend and Victor. That were copies of the Hardinge HLV-H.

HARDINGE BROTHERS, INC. ELMIRA check the part description to make certain the assembly and/or individual part applies to your machine. .. Bed. 2. Screw. 2. Washer. Front Screw. Lock Washer. 6. 14 D V. 0 0 1 0 2 1 4. D V B 0 0 0 9 7 7 6. 0 5 5 0 3 0 5. N 3 7 0 0 0 0 7 3 6. 5 p. 0 0 0 6 4 3. HARDINGE DV59 DSM59 Lathe Part Manual DV DSM [Misc.] on Amazon. com. *FREE* shipping on qualifying offers. Number of Pages: 15 This is a. DV59 Precision Lathe and DSM This is a reproduction, not a photocopy, of an original Hardinge DV59 Precision Lathe and DSM59 Second Operation.

| Author: | Yomuro Vur |

| Country: | Libya |

| Language: | English (Spanish) |

| Genre: | Music |

| Published (Last): | 6 September 2011 |

| Pages: | 471 |

| PDF File Size: | 19.62 Mb |

| ePub File Size: | 11.13 Mb |

| ISBN: | 836-5-96415-907-1 |

| Downloads: | 82775 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Yozshujinn |

I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. Why settle for anything less? Now the haedinge belt can be removed 8.

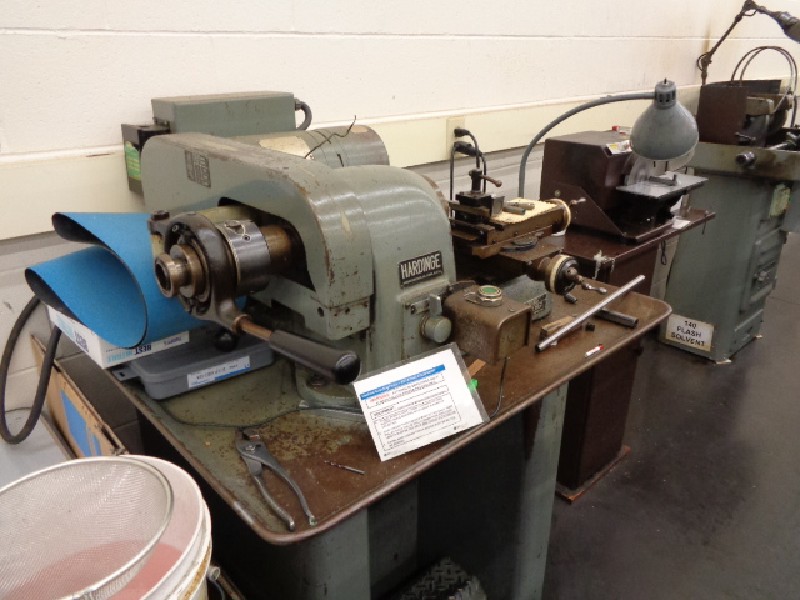

Hardinge DV59

All features work as they should. Page 1 of 3 1 2 3 Last Jump to page: What is the torque of stepper motors?

Not Sure of How Accurate the Next, mount a block to the rear ballnut, but allow it to freely spin with the nut up and down the screw.

Swing Over the Bed: I stare into the headstock and for the life of me I am missing something, I see no setscrews or spanner to loosen the spindle pulley. Like us on Facebook.

I propose to complete this project in two phases Phase I I will keep the head and spindle of the DV 59 lathe as it is, driven by 1 HP induction motor. The bed width is approx. It is a good idea to focus on one particular project. If my mill had sufficient travel to mill flat and parallel in one operation the relief for the THK rails and lathe body I would probably still use it.

The table is to be mounted on the lathe bed and fixed to the bed so that the cross slide – 7. Take gearbox off if changing the top spindle belt 3.

Spindle Nose Cover Guard. Extra tooling to include: Number of bids and bid amounts may be slightly out of date. Update, Ok, the 12″x36″x1″ plate that was purchased I am just no happy with, too much warp and bow.

Read over relative threads, not just this one but others here as well and then you will be in a better position to begin how best to accomplish the conversion.

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly.

Hardinge DV, DSM, TFB-H, HC-AT, HSL & HC Lathes

Had some delay in getting a reasonably straight piece of steel, it is still on the mill waiting for some truing up for the rails and the area where it will bolt to the DV lathe body. Remove back motor panel 4. Note that these drawings have change numerous times so even these may not be the last, however for my first attempt at this conversion these should be it. I do have the carriage blocks drawn up and tool paths for when they get machined. Tags for this Thread anotheravailablebedcncdvforumfourkeeplatheoperasightable.

Hardinge Hsl Lathe Manual

The imported mill and drill table purchased from ebaystore. Board index All times are UTC.

There is also a full length rib down the center of the bed about 1. What software are you using? Mine actually has the bar with the wheel that goes through the spindle and screws onto the collet, but it is missing the entire lever arm assembly. I am new to this forum. The time now is The torque of motors will be decided depending on the condition of table.

Hardinge Hsl Lathe Manual Pdf

In the second view, the top table is removed. Alternately depending on the dimensions of the longitudinal table, holes can be drilled and reamed in the side of the table so that the tool mounting arrangement is similar to the Hardinge turret tool mounting system. I invite your comments and suggestions on this project and specifically would like to know: Thanks Neatman, I might trade or buy that collet closer from you. We bought 3 of the Hardinge DVs and I’ m looking for parts to get them setup and cnc conversion options out there.

When it came time time get the belts off this I was scratching my butt for a while before I remembered the shaft pulling out of the bearing.

The table is to be mounted on the lathe bed and fixed to the bed so that the cross slide – 7.

Hardinge Hsl Lathe Manual Pdf